- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

KLDA Automatic Rotary Creasing & Die Cutting Machine

-

Product Description

Features:

Paperboard Feeding Part:

◆Adopts lead edge feeding system. Adjust wind volume according on cardboard bending degree to ensure feeding paper smoothly.

◆The rubber roller with air cylinder device, feeding accurately, stably, and avoid destroying paperboard when the feeding space is very small.

◆The left and right side baffles adopt electric adjustment, the front baffle space manual adjustment.

◆Equipped with colors touch screen take 360 degree set to die roller, display product speed and set production quantity.

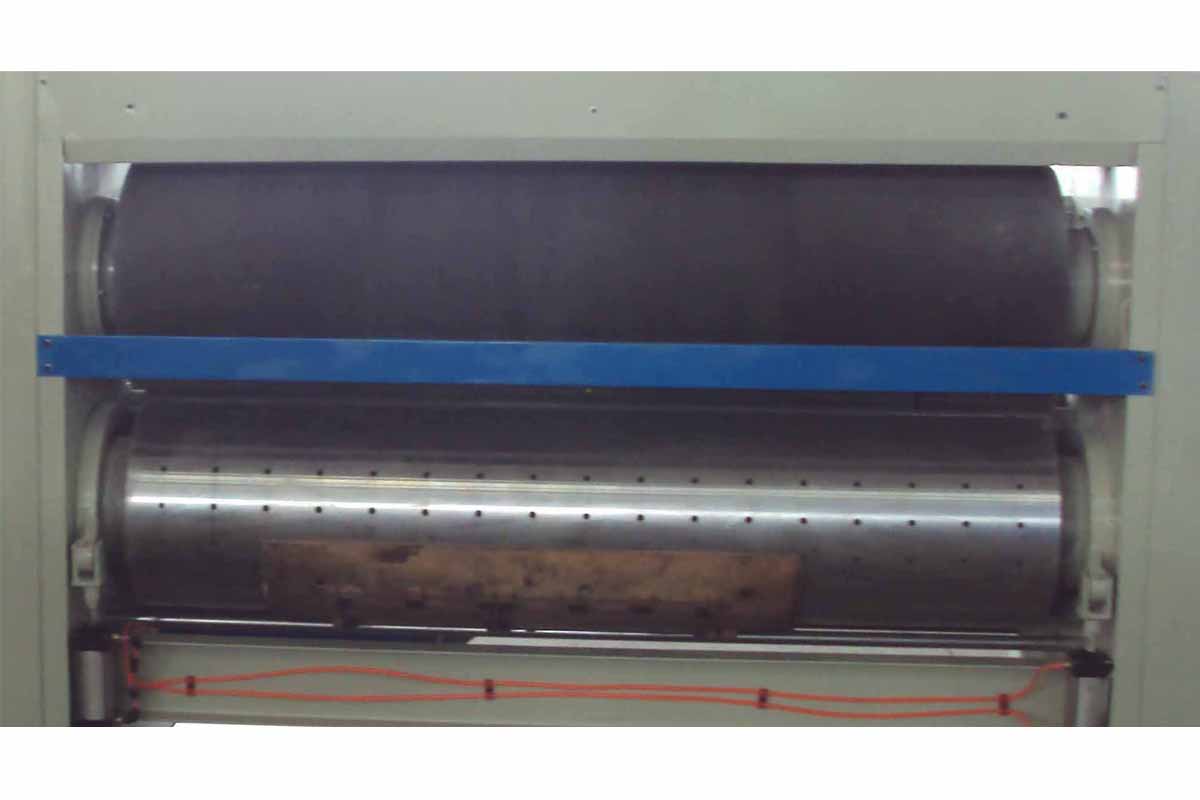

Die Cutting Part:

◆Die-cutting roller adopts the high quality steel materials, 30mm thickness, balance correction, hard-chrome plating.

◆Wallboard adopts high-quality cast iron material, 50mm thickness.

◆Soft-roll automatic grinding structure to improve service life of rubber cover. The rubber cover can be grinded 3-4 times.

◆Line speed automatic compensation to ensure that die cutting size of each batch of cardboard boxes is the same;

◆It adopts the imported CUE Polyurethane carpet sets from theU.S., which is easy to install and can die cut twelve million times;

◆Mechanical soft roll about 40 mm lateral movement; the pads wear evenly;

◆The six grade grinding gears adopt 40cr material. It is characterized in low noise and long service lift.

◆Die-cutting roller cylinder automatic separation devices to reduce wear of rubber cover.

NC Part

◆PLC control system is reliable.

◆LCD touch screen

◆Frequency speed adjustment can save power and is reliable and smooth..

◆The whole machine adopt photo-electricity, electricity and gas combined controlled.

Main Specification:

Model

Drum diameter

Max sheet size

Min sheet size

Speed

Total power

KLDA-1500

φ410

1500*1350mm

320*500mm

0-80pcs/min

5.0kw

KLDA -1750

1750*1350mm

320*500mm

0-80pcs/min

5.0kw

KLDA -2000

2000*1350mm

320*500mm

0-80pcs/min

5.0kw

KLDA -2250

2250*1350mm

320*500mm

0-80pcs/min

6.0kw

KLDA -2500

2500*1350mm

320*500mm

0-80pcs/min

6.5kw

KLDA -1500

φ487

1500*1500mm

450*500mm

0-80pcs/min

8.5kw

KLDA -1750

1750*1500mm

450*500mm

0-80pcs/min

9.5kw

KLDA -2000

2000*1500mm

450*500mm

0-80pcs/min

10.5kw

KLDA -2250

2250*1500mm

450*500mm

0-80pcs/min

11.0kw

KLDA -2500

2500*1500mm

450*500mm

0-80pcs/min

11.kw